I wanted to get some 100 microhenry chokes to experiment with, so I ordered a bunch from BG Micro. Also, I found they had some Steward 2B0686-100 EMI Suppression Filter, which once I cut through all the gobbledygook, came down to toroid cores. So I ordered a dozen or so of those. Then I found they had Dual Coils on Ferrite, so I ordered some of those. They quickly shipped the order and they refunded 3 bucks by shipping them by USPS.

Toroid Cores – . I should point out that these cores are made to go over the cable from the PC to the monitor, printer or keyboard, etc. Typically these suppressor sleeves are high permeability, several thousand. I opened up the package today and got down to work. I took one of the toroid cores and put a short piece of wire through the core and measured the inductance at 1.58 uH. I wound 16 inches of 24 AWG telephone wire on it totaling ten turns, and measured the inductance at 152 uH. I took another core out of the bag and wound two lengths of the same wire bifilar again ten turns, and it measured 145 uH. The third and fourth cores wound the same way measured 142 and 145 uH respectively. I haven’t made a Joule Thief yet with one but I think these should make a good JT toroid

Dual Coils on Ferrite – I took one of the already wound coils out of the bag and measured the inductance. The green winding measured 1.91 mH, and the red winding measured 921 uH. I measured a second one and got 2.0 mH and 948 uH. The third one measured 1.98 mH and 951 uH, the fourth one measured 1.92 mH and 914 uH, and the fifth measured 1.85 mH and 889 uH. The BG Micro website’s page (link above) says the windings are 1.65 mH and 600 uH. I’m using an LC Meter IIb, which has an accuracy of 1 percent and really does measure chokes marked 100 uH right around that value, so I trust its measurements. The values I measured are close to the standard values of 2 mH and 1000 uH, so for those reasons I think that my measurements are more accurate than the ones given in the BG Micro web page. I measured one winding diameter at 0.024 inch, so I think the windings are wound with 23 or 24 AWG enameled wire.

Dual Coils on Ferrite – I took one of the already wound coils out of the bag and measured the inductance. The green winding measured 1.91 mH, and the red winding measured 921 uH. I measured a second one and got 2.0 mH and 948 uH. The third one measured 1.98 mH and 951 uH, the fourth one measured 1.92 mH and 914 uH, and the fifth measured 1.85 mH and 889 uH. The BG Micro website’s page (link above) says the windings are 1.65 mH and 600 uH. I’m using an LC Meter IIb, which has an accuracy of 1 percent and really does measure chokes marked 100 uH right around that value, so I trust its measurements. The values I measured are close to the standard values of 2 mH and 1000 uH, so for those reasons I think that my measurements are more accurate than the ones given in the BG Micro web page. I measured one winding diameter at 0.024 inch, so I think the windings are wound with 23 or 24 AWG enameled wire.

I soldered together a Joule Thief (see photo) using a PN2222A transistor, 1k resistor, a blue-green LED, and the BG Micro dual coil ferrite core toroid. The circuit drew a respectable 82 mA at 1.5V supply voltage. I used the green winding for the primary and the red winding for the feedback winding. As can be seen, the LED lit up brightly.

I swapped the primary and feedback windings, just to see how well it would work. The supply current went up to 90 mA at 1.5V. The frequency was 5.4kHz. I turned the supply voltage down to see how well it would work, since the feedback winding had half again as many turns as the primary. The LED was still glowing at 0.35v, and extinguished at 0.32v. The LED came back on when the supply reached 0.48V. This means that it will make a good JT for really depleting the battery. I also noticed that there is enough room in the hole in the middle to wind another winding, but I haven’t tried it to find out how many turns it can hold.

I was in for a surprise – I then opened up the bag of 100uH chokes and measured one and was surprised when it measured 79.5 uH. I pulled another one out of the bag and it measured 77 uH. The third through 10th chokes also measured between 77 and 79.5 uH. The silver band means that the tolerance is ten percent so the inductance should be between 90 and 110 uH. But these are more than 20 percent too low!

I had pulled these out of the bag with no particular order and my conclusion is that all of the remaining chokes in the bag are also around that value. There are a few possibilities why these are not the correct value. One is that they are ‘culls’. In other words, they are left over after the ones that are within tolerance are picked out. Another possibility is that the 100 uH value marked on them is the wrong value; they should have been marked 82 uH which is the closest standard value. Of these possible scenarios, it seems to me that this mismarked value is the best answer. Why? Because all of the chokes I measured (and most likely all of the rest) were all tightly grouped around a certain value. If they had been culls, the values would be scattered widely. I contacted BG micro about this and find out how to get a refund or some resolution. I’m waiting for a reply.

I received a reply back. They said they measured some of the same part number and they all measured about 100 uH. They then asked if mine were marked brown, black, brown (they are), and suspect that my LC meter might be wrong. I pulled another ten chokes out of the bag and measured them, first with my LC IIb 1% meter, and then with the LCM from China, which seems to be 5 or 10 percent accurate. Both meters measured the ten chokes in the high 70 uH range. I then pulled five 100uH chokes from my parts bin and measured them with both meters, and they all measured close to 100 uH. I took pictures of both of the measurements and emailed them in my reply. Right now I’m thinking they must have not measured the right part, or else their meter is wrong. I’m waiting for their reply.

The reply came. It’s kind of weird. His AADE LC IIb (same as mine) measured all 20 chokes at an average of 76 uH. He then measured them with a Velleman DVM6243 and they measured 105 uH average. He then used a B&K circuit tester and the chokes measured just over 100 uH average. So he offered a few things, one was to give me my money back.

I’m thinking about this, and trying to come up with another way to test the chokes. I think there’s something else affecting the measurement. It could be that the meters are measuring too close to the self resonant frequency and this causes result to be low. I’m going to do some calculations and see if I can build a circuit that will oscillate with a known value of capacitance and I can the calculate the inductance from the frequency of oscillation.

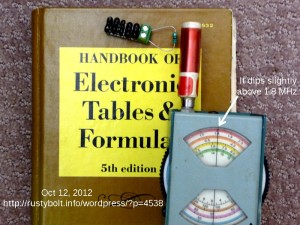

I changed my strategy (see the attached photo) – I eliminated any inductance meter that might influence the reading. Instead of building a circuit, I used my Heathkit Dip Meter. Not much here that can influence the resonant frequency. The dip meter doesn’t measure anything, it generates a frequency and when the coil is near a resonant circuit, the dip meter shows a drop in current when the variable capacitor is set to the resonant frequency.

I changed my strategy (see the attached photo) – I eliminated any inductance meter that might influence the reading. Instead of building a circuit, I used my Heathkit Dip Meter. Not much here that can influence the resonant frequency. The dip meter doesn’t measure anything, it generates a frequency and when the coil is near a resonant circuit, the dip meter shows a drop in current when the variable capacitor is set to the resonant frequency.

I put five 470 pF silver mica capacitors in series, which gives 470/5 or 94 pF. These are precision 1 percent capacitors – they’re very accurate. I measured them and they measured 96 pF; the extra 2 pF came from the small circuit board and wiring. I put one of the chokes in parallel with this 96 pF capacitor.

I got my handbook of formulas and found the formula for resonance. Note: the inductance can also be found by going to this calculator and inserting the frequency and capacitance values and clicking on calculate. I used the handbook to calculate two resonance frequencies, one for 96 pF and 100 uH, which was 1,624,368 Hz or 1.624368 MHz. The other was for 96 pf and 78 uH, which was 1,839,235 Hz or 1.839235 MHz.

I then set the choke / capacitor resonant circuit next to the dip meter and adjusted the variable capacitor until the meter read a dip, indicating the resonant frequency. I got the dip when the variable capacitor’s dial read a bit above 1.8 MHz. This indicates without a doubt in my mind that the choke is 78 uH, since the dip frequency matches the frequency calculated for 78 uH. My conclusion is that all of these chokes are somehow labeled wrong and that I’m requesting a refund.

Update Nov 2 – The guy from BG Micro just sent me an email saying that he measured them with a different LC Meter IIb and with a HP network analyzer. The chokes measured 70 uH at low frequencies, but at 3.5 MHz, they measured 100 uH. I have a lot of confidence in the LC IIb at that 100 uH point, and I would bet my first born on the HP analyzer, since it’s definitely a class above the rest. So I have no doubts that they are giving correct values.

But the question is, what would be causing the chokes, which are marked 100 uH and 10 percent tolerance, to be so far off at low frequencies yet measure okay at 3.5 MHz? What kind of core material is frequency sensitive? Also, I’ve dealt with chokes at frequencies below and near self-resonance, and the inductance goes down as the frequency goes up toward self-resonance, not UP!

I can understand if you have a choke with DC going through the core and the magnetic field generated by the DC is causing the inductance to change. But to my knowledge these meters do not put any DC through the choke during measurement. This is some rather odd behavior that I have never seen before.

Update Nov 15 – I tack soldered together a Colpitts oscillator consisting of one PN2222A transistor, a pair of 470 pF, 1% precision silver mica capacitors in series, giving 235 pF, and the BG Micro 100 uH choke, plus the resistors for bias and load. I measured the two capacitors without power and without the choke, and got 273 pF with my LC Meter IIb. This value is higher because the power is off, so I will instead use 245 pF (as the value for the two capacitors and the parasitic capacitance of the transistor and other components) when I do the following calculations.

Update Nov 15 – I tack soldered together a Colpitts oscillator consisting of one PN2222A transistor, a pair of 470 pF, 1% precision silver mica capacitors in series, giving 235 pF, and the BG Micro 100 uH choke, plus the resistors for bias and load. I measured the two capacitors without power and without the choke, and got 273 pF with my LC Meter IIb. This value is higher because the power is off, so I will instead use 245 pF (as the value for the two capacitors and the parasitic capacitance of the transistor and other components) when I do the following calculations.

The circuit oscillated in the middle of the AM broadcast band at 1130kHz – I used an AM radio to find the frequency. Using the formulas for resonant frequency, capacitance and inductance, I calculated the value for the BG Micro choke’s inductance at 80.97 uH. This is more than the 78 uH in previous measurements, but it’s still nowhere near the 100 uH plus or minus 10% allowable for the inductance that it is supposed to be.

To verify that my circuit and calculations were accurate, I got a 100 uH choke and put it in place of the BG micro choke. I found the RF carrier at 995 kHz, and I calculated the inductance at 104.4 uH. I measured the inductor at 104 uH before I installed it in the circuit, so my measurements and calculations agree fairly close with the measurement on the LC Meter IIb. This makes me feel confident that these measurements are reasonably accurate. Also, since all of the four measurements agree with each other, I’m confident in saying that the value of the BG Micro choke really is approximately 78 microhenrys plus or minus several percent.

Back to experimenting…