Homemade Adjustable Capacitor

I read that the 365 pF air variable capacitors are very expensive, $30 or more so I decided to try to build one. It’s not difficult to make an adjustable capacitor out of materials one may have at home. This one does not adjust easily, it’s more of a prototype. I got an idea to use simple, easily obtainable materials.

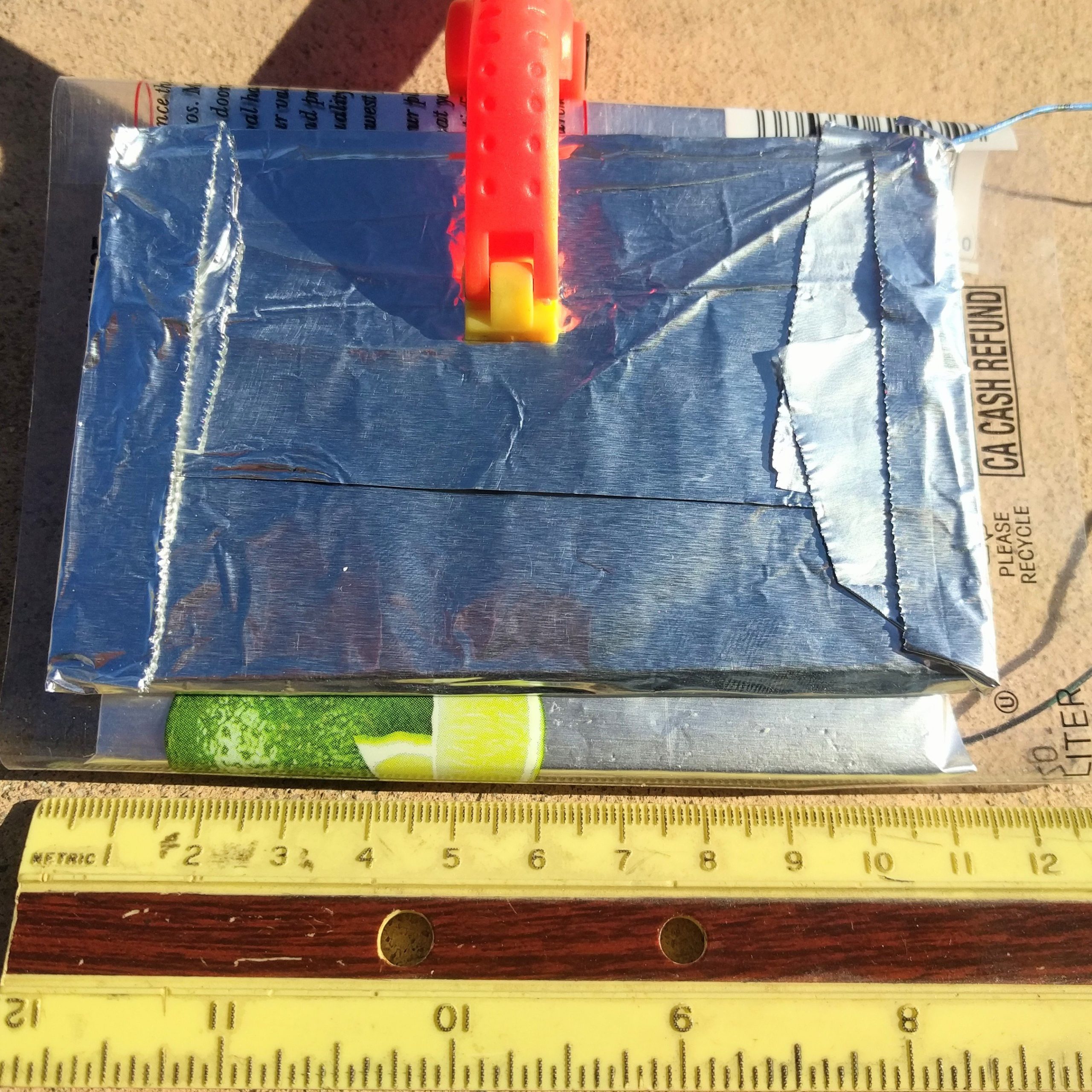

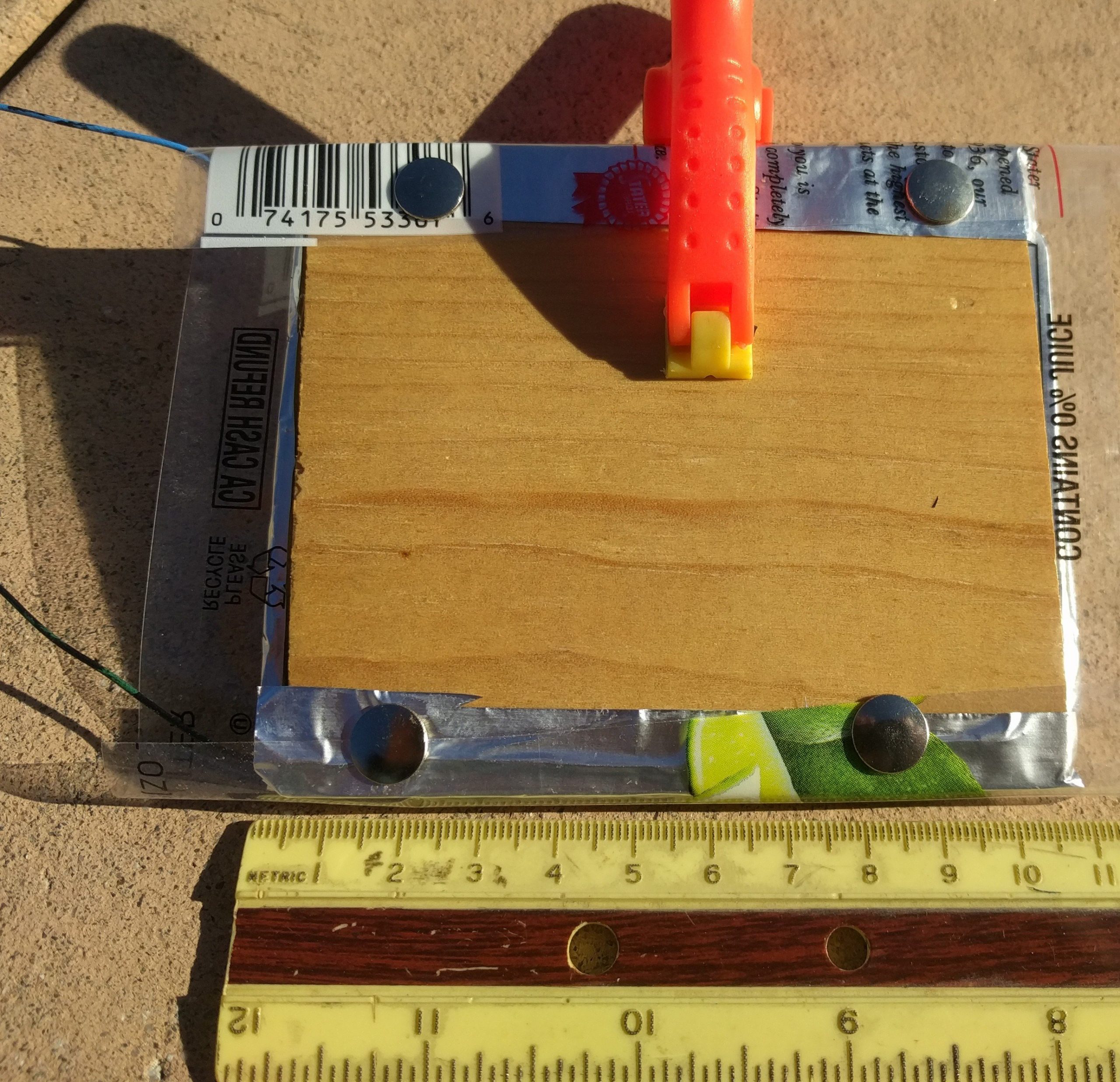

See the photos. The homemade adjustable capacitor has five layers. The bottom or fixed plate is a piece of 3/8″ or 9mm thick by about 3.5″ or 80mm square pine board. This is covered by a layer of aluminum foil and the dielectric which is made of a . 001″ thick plastic label from a soft drink bottle. Both layers and the wire are held tight to the pine board with four thumbtacks on the backside. The other moveable plate is made from three layers of cardboard cut from a cereal box and glued together with white glue. This is covered with aluminum foil and the wire is tucked under the foil. The two plates are held together by a plastic spring clamp.

The capacitance while fully overlapped is from about 1000 to 1500 picofarads depending on how much pressure is put on the moveable plate – it’s not stiff enough and doesn’t fit flat on the other plate. It should be thicker and stiffer, made of wood or a piece of aluminum. The capacitance is adjusted by releasing the spring clamp and changing the amount of overlap of the two plates. The amount of overlap can’t be lowered too much because the plates will fall apart. What has to be done is to cut the foil away partly on both plates so that they can be held with the spring clamp while the foils have no overlap.

The plates should be narrower and longer, like 1.6″ or 45mm wide and 10″ or 250mm long. This will allow the plates’ overlap to be adjusted in smaller increments. Also the typical adjustable capacitor needs to be about 500 pF so the capacitance can be lowered. This can be done by cutting the plates as above or using a thicker plastic for the dielectric. Some homemade adjustable capacitor designs are cut semicircular, so the plates pivot about the axis of the circle. The plate overlap can be adjusted by moving the circular plates.

Some old radio building plans used two sheets of aluminum foil with pages of a book between them. The closed book could adjust the capacitance by varying the pressure or weight on the book.