This is a continuation of the original June 14 blog.

I don’t think I mentioned this earlier, but the 44 LED light circuit is so simple that there is no regulation, so the LEDs can be dimmed by reducing the AC voltage. I used a sine wave variable AC voltage. But most conventional dimmers use a circuit that chops out part of the AC sine wave every 1/120 of a second. During the time the dimmer is on, the peak voltage can still be over a hundred volts, but to the incandescent bulb, it looks like the low AC voltage on the average. The problem is typical CFL and LED lights don’t see it this way; they see the peak voltage and dim very little.

WARNING: With all the exposed bare wires that are easily touched, there is a great danger of being shocked. That’s why I set the measurement up before I applied power.

I arranged the LED panels on the wood floor and connected up a DMM to one 6-LED panel, and the other to the AC input. For the AC input I used a variable AC source, the same sine wave as from the AC line. I adjusted the AC to various voltage and these are some of my observations.

The LEDs start to glow at about 40 VAC. Not enough light to illuminate.

They put out decent light at about 75 VAC, and the DC across one of the 6-LED panels was 17.14 VDC.

At the following AC voltages, the corresponding DC voltages were:

90VAC == 17.53 VDC

110 VAC == 17.89 VDC

115 VAC == 17.93 VDC

120 VAC == 17.98 VDC

125 VAC == 18.04 VDC

After the test, the 6 LED strips got moderately warm. But it must be pointed out that they were spread out on the floor, where plenty of air could get to them. I’m sure that they would get much hotter when they are packed into the light base.

Some Calculations

My objective is to find out how much current each LED needs. I want to disconnect the six LED strips from this LED light and mount them onto a flat heat absorbing surface. I can then add six current limiting resistors and a power supply Each strip has 5 holes, so I could screw two small screws through the holes to mount it to a thin flat strip of aluminum. I can then mount this under the cupboard in the kitchen, and have a 6W LED strip light that lights my kitchen counter.

According to the measurements, six LEDs in series have about 17.96 VDC across them when the AC line is 117VAC. Therefore a single LED should have about 17.96V/6 or 2.993V. And since there are 22 LEDs in each series string, the total DCV across them is about 65.85VDC.

117VAC rectified and filtered is about 165.5VDC, and subtracting 1.2V for the full wave bridge rectifier, leaves about 164VDC. Subtracting the 65.85V, leaves 99.6VDC. It takes an AC voltage of 99.6 / sqrt(2) to make the 99.5VDC, which calculates to 70.43VAC. So the circuit has to drop 70.43 VAC volts across the capacitors.

So far, I don’t know what the total LED current is, because I have not connected an ammeter in the circuit. But we know that the total of the two rust red capacitors is 3.7 uF.

The reactance of 3.7 uF at 60 Hz is 717 ohms. I divide the 70.43 VAC by 717 and it is 0.098 amps. The total current through both strings of 22 LEDs in parallel is 98.2 milliamps. Assuming that this current is split equally into 1/2 for each string, that gives 49 .1 milliamps for each string of 22 LEDs. So we now know that each LED has a little less than 50 milliamps going through it.

I found the V drop across each LED was 2.993V or about 3 volts, and the current was 50 mA, so each LED is dissipating 150 milliwatts.

With the above information I can calculate the current limiting resistor needed for a given supply voltage and a strip of 6 LEDs. Assuming that I have a 24VDC supply and the LED strip requires 18V, the resistor must be 6V / 0.05 A, or 120 ohms.

Update June 22 – In his comment, Kirk reminded me that these low power AC line operated devices typically have a resistor or NTC resistor in series with the incoming AC line . I have often seen the resistor, typically 100 ohms as he noted, in series with the incoming line, but I have never seen a NTC (negative temperature coefficient) resistor used, and I’ll explain why. But first I have to tell my experience with these type of devices.

I have often seen the NTC devices, which typically look like a thick ceramic disk capacitor, in switching power supplies. They are used to limit the inrush ‘surge’ current when the power supply is first turned on, and as they heat up over a few seconds, their resistance drops to the point where they let the full current through with very low resistance. Less strain is put on the power supply diodes and filter capacitors, and they are protected from damage from the high surge current.

I maintained a large PBX system, with over a thousand phones. Each digital phone was connected to the PBX, which furnished 48 volts DC to power the phone. On the PC boards in the PBX, each phone line was connected to the 48 volts through a special resistor, which as I just said, looked like a thick ceramic disk capacitor. But this was not a NTC resistor, this was a PTC resistor. It had very low resistance, something like 8 ohms, as long as it was cold. But when it heated up, the resistance would increase to the point where the 48 volts could force only a hundred milliamps through it. This resistance was several hundred ohms, but depended on the temperature. If there was a short somewhere out there in the thousand or more feet of phone line, this PTC would protect the line from excessive current. It kind of acted like a fuse, however it had two advantages: it did not burn out, and it ‘reset’ itself (cooled off) once the short was removed.

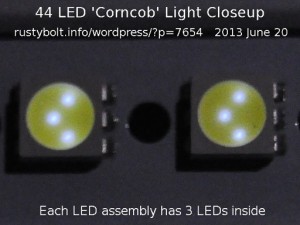

Well, the PBX is gone but I scrounged hundreds of those PTC resistors from the boards in the last few years, along with other unique parts. But going back to the LED light, the reality is that there are no active parts in this corncob light, just a bridge rectifier, filter capacitor, which happens to be rated at twice the maximum rectified voltage, and a series string of LEDs. The reactance of the two capacitors acts as a current limiter at 60 Hertz. There is no need for an inrush limiter when the light is powered on.

However, when the AC line voltage frequency is greater than 60 Hertz, the reactance of the current limiting capacitors is less, and the current could be much higher. But when is the frequency greater than 60 Hz??? Whenever there is a spike of voltage, which may occur whenever an inductive device such as a motor, relay, or similar device with a coil is connected to the line. These have sharp increases in voltage and can go right through the current limiting capacitors like they were not there. So the circuit designers decided that it would be best to put a resistor in series with the capacitor, so that there would be some limit to the maximum current.

Also, it should be remembered that when the NTC is used in a power supply, after the initial turn on, their resistance is very low and they offer almost no protection against voltage spikes that might be on the AC line.

A suitable MOV – Metal Oxide Varistor – mounted across the AC input should serve to protect the circuit from overvoltage transients. A MOV is the magic sauce in inexpensive surge protector power strips. They’re a 20 cent part for the rating for this type of application.

This is wholly separate from the series resistor (or NTC) intended to limit inrush current when the AC capacitor initially goes to charge up, which itself is is separate from the 500K-1M resistor across the legs of the AC cap intended to bleed it off when AC is removed.

Another poster and I had a serious discussion in a newsgroup on Usenet long ago. He convinced me that the “magical sauce” you mentioned was not what it seemed to be. The conclusion was that most residential dwellings don’t have adequate grounding for the MOVs to work properly (the same applies to commercial buildings, but I won’t get into the idiosyncrasies of three phase power).

Another reason is that the 20 cent part increases the price of a power strip, sometimes to more than double. This is the ultimate marketing tool (in other words, ripoff of the consumer). You get a ten percent discount on a piece of electronics or PC, and the salesman insists you buy a surge protection power strip, and if you say no, he predicts dire consequences. He sells one to you and makes up for the discount and then some. And don’t forget the USB cable, another excessively high profit margin item.

Since then I’ve encountered three cases of the MOVs burning up; one right when I was there, and it was as violent as the exploding banana I blogged. Scared me to the bone because I heard it and smelled it but I couldn’t find it, and I was extremely worried about a fire starting. Fortunately the power strip that burned up was all metal and I could unscrew the screws and see the total incineration the MOV had done to itself. There may be a(n extremely restricted) insurance covering damage to the protected equipment, but you won’t see fire insurance. From then on, I’ve tirelessly tried to eliminate them and convince others to do so too.

I’ll address the other stuff in a following comment.