I’ve built an FM microphone bug or transmitter before, but it’s been a very long time since I wound coils for one. Long ago I would wind too many turns on the coil and try it out. The usual outcome was the bug would be transmitting somewhere in the low TV channels 5 or 6, which are from 76 to 88 MHz. just below the FM band. I could see herringbone patterns on the TV screen. Then I would use a ‘grid dip meter’ to find the signal and its approximate frequency. Then I could remove a turn from the coil and repeat the process until the bug was transmitting slightly below or at the low end of the band. I could then spread the coil windings apart or remove some pFs from the tuning capacitor(s) to get the frequency where I wanted it. This used to be just above 90 MHz but then a station started using that frequency so I chose a lower frequency.

But nowadays there are no analog TV stations below the FM band, so the TV can’t find them. And it’s just better to design and build the coil to be the right inductance before it’s put in the circuit. The typical coil I used long ago was somewhere in the 0.100 to 0.150 uH range, with 125 to 135 a good value. The problem is how to wind a coil the right diameter, length and wire thickness to be the right value.

The circuit I’ll use is a cheaper FM Bug circuit, a single transistor version. This does not use a microphone preamplifier transistor, it has the microphone connected directly to the RF oscillator. This means the microphone is not very sensitive and has to be close to your mouth. But it is simple and easily built.

There are a few changes I will make to the circuit. Since 9V batteries are so expensive, I will instead use four 1.5V AAA cells in a battery holder for 6V supply. I will change both 47k resistors to 22k. Also change the 220 ohm resistor to a higher value, 330 to 470 to save batteries. The 1 uF microphone capacitor is a bit too high, a better choice is a 0.1 uF.

One thing they forgot is a bypass capacitor across the battery. This important to the radio frequency. There should be a 0.01 uF ceramic disk capacitor from plus to minus, and keep the leads short. All of the leads should be short on the parts. The antenna is not needed for use within 30 feet or 10 meters of the radio receiver.

The BC547 is a good choice, but I have a lot of 2N3904 transistors, which is also a good choice. Just about any small, low power NPN transistor will work, such as PN2222A, 2N4401, 2SC945, etc.

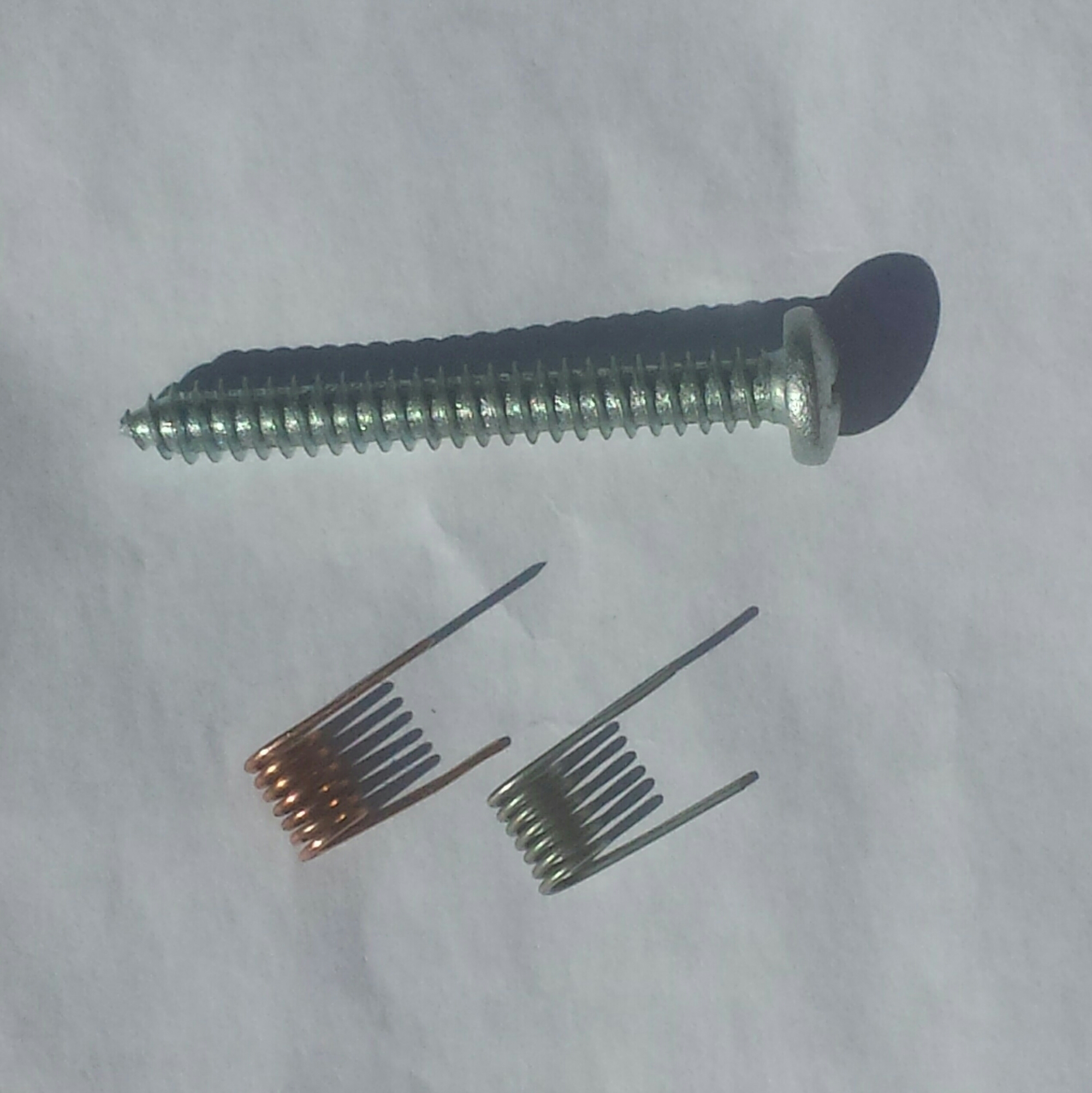

The coil has to use a short length of wire that is stiff enough so that it won’t bend while being handled. The wire I chose was 20 AWG solid wire which is 0.032 inch or 0.813 mm diameter. I chose 20 AWG because it is available at hardware or home improvement stores. This can be 2 conductor door bell wire or multiple conductor thermostat wire. This wire is usually bare solid copper and has insulation. The wire needs to be about 6 inches or 150 mm long. This will give a total of 6.5 turns.

The plastic insulation has to be removed. I used a wire stripper, but it’s important to not nick the wire. I use a utility knife or exacto knife and cut off a half inch of insulation so I can grab the copper wire with a long nose. Then I can pull on the insulation and it slides off the copper wire.

The wire needs to be wound around a form to give the coil a consistent diameter. I chose a large sheet metal screw as the winding form. The size of this screw is a number 14, and the inside or minimum diameter between the threads is 0.180 inch or 4.57 mm. The length of the screw was 1.5 inches but this can be any length as long as it can be held easily as the coil is wound around it. The thread pitch or threads per inch is not important because the coil will be compressed to give a coil length of 0.33 inch or 8.46 mm.

I started winding so there was about 3/4 inch of wire for the lead. After I wound the wire around the screw 6.5 turns, there was excess wire, which I cut off. Let me explain the difference between 1 turn and 1.5 turns.

|

O 1 turn

| The wire starts on the bottom left, loops around one turn and ends on the top left. The ends point in opposite directions.

O 1.5 turns

| | The wire starts on the bottom left, loops 1 turn (where it would be pointing upwards) then continues around another half turn where it stops bottom right. The ends point in the same direction.

I unscrewed and removed the screw. Then I squeezed the coil on its ends until it was 1/3 inch or 8.46 mm long. All of the turns were evenly spaced and were not close enough to touch. The coil looked evenly wound.

This coil is sturdy enough to keep its shape during circuit construction. Once the circuit has been built and the frequency adjusted to be on the low end of the FM band, the coil should be secured. This can be done a number of ways. The coils in radios made years ago were secured by inserting a small piece of foam sponge, and a few drops of melted paraffin or candle wax were dropped on it so that it prevented the coil from moving or vibrating. But today, any kind of thick glue can be used. Hot glue, silicone or epoxy will work, but whatever glue is used, it should not shrink as it dries, so the coil does not change shape. Paraffin or candle wax will also do the job. Another important thing this does is insulate the bare coil wire and prevent the turns from touching.

In the past, I have used a short length of soda straw inside of the coil, with glue to hold the coil in place. In this case the inside diameter of the coil is too small for a straw, but a small piece of plastic or similar would work. I have used wood in the past, but now I would avoid using it because in dry or wet weather wood shrinks or swells with the humidity changes. This could change the frequency a small amount. This also reminds me to tell about the rest of the circuit and its importance in frequency stability.

The circuit schematic shows the parts values but says little about these parts.

The transistor has some influence on the frequency, mainly with temperature changes, so it is best to keep it cool and not in hot sunlight or near any hot or cold air, where the temperature is not stable.

The resistors have very little influence as long as their leads are kept short.

The capacitors have a lot of influence, except for the 1000 pF capacitor from base to negative, and the .01 uF from plus to negative. Typical capacitors used are ceramic disk, and keep the leads short. The microphone coupling capacitor, a 0.1 uF, can be any type. Lead length is not important.

The remaining capacitors determine the frequency.

The capacitor across the coil has the most influence on the frequency. This is the tuning capacitor, and resonates with the coil at the transmitting frequency. For the frequency on 89 MHz the 0.125 uH coil must have 25 pF total connected to it. Of this total, the capacitor will be 18 pF and there will be approximately 7 pF in the transistor and the other capacitor connected across the emitter to collector of the transistor. This capacitor will have a value of 4.7 pF which is a small value often difficult to obtain. It can be made from two short lengths of insulated wires twisted together. Some glue or epoxy will help keep the circuit stable. It also is important that the circuit is mechanically stable so that the parts don’t move or vibrate.

There are many online aids to building this circuit. Some help can be found in videos found on YouTube or other similar websites. Some projects have good instructions on building this circuit. Do searches and read or watch some instructions to get an idea of what will help you to have good success with this project.

Note: Some kits and circuit boards have a PC board trace in place of the coil. This is typically a square or C shaped loop about 1-3/8 inch or 35mm across, and has about the same inductance as the coil, about .13 microhenry. Since this is a part of the printed circuit, it has the same inductance for each and every PC board made. This eliminates guesswork and the time needed to make the coil. The loop is very stable, as stable as the circuit board. I have built a similar coil using heavy 12 AWG bare solid copper wire. It worked good.